Automation is highly substantial for heavier transportations and transmissions. In certain circumstances where conversation with construction lines are encouraged, automation will soon be of good help. Check out the different subclasses and different employs for these conveyor technologies.

You can find five well-known subcategories for automatic conveyors. First on the list is just a pneumatic conveyor that employs compressed air and cleaner pipes to make the process operate. Next could be the shaking conveyor that is made to be able to transportation volatile goods from region to another. That technology has the capability to sort out the things before they are given to one other end.

The strip conveyor is another popular subclass for computerized conveyor systems. The engineering operates with the current presence of looped material devices and rubber links. These are common in shifting airport luggage. There is also a chain conveyor that’s generally used in the automotive industry. It works with a big sequence that moves among two pulley wheels. The screw conveyor may be the fifth kind and is relevant in water programs for agricultural needs. The mess in that conveyor engineering form makes the result benefit transportation of varied materials.

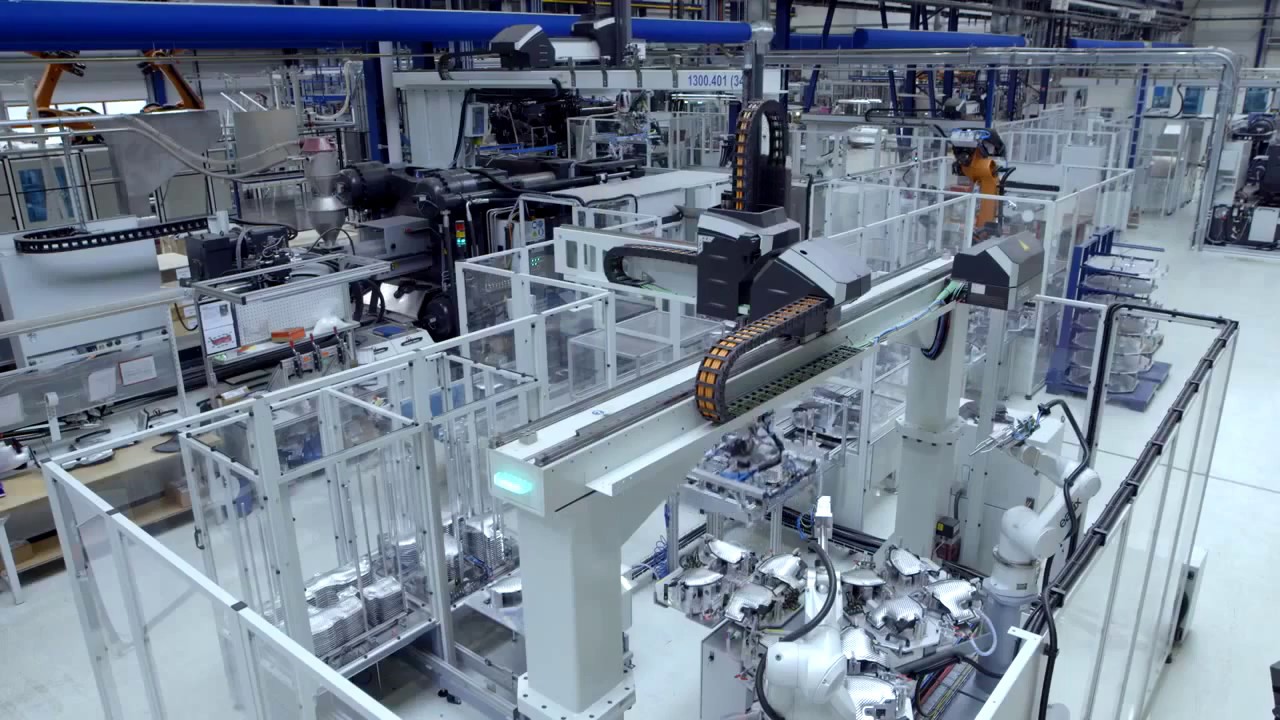

Apart from the industries served by the many types of computerized conveyors, there are however different applications for the professional product. Essentially, it is applied to be able to simplify handbook procedures in all areas of operation. Which means that it has the power of solving issues on information transport of goods. With automated versions, you can find you can forget hassles in doing the tasks in production. These systems are extremely ideal than different subcategories of mechanized paint finishing systems in that they are better to cope with and no more require rigid training for operation.

But there’s one portion a organization should pay attention to to make computerized conveyor methods work and that is to undergo system maintenance. If this may perhaps not be met, wear and tear of the device is going to be inevitable. Normal cleaning of the conveyors and exchanging the ruined elements are crucial in the preservation process.

Automated conveyor systems are now being significantly utilized in different industries for the secure transport of components since they reduce individual labor and increase efficiency. A gear conveyor process is straightforward to install in a warehouse and is significantly easier to work than a forklift and different related heavy machines. It can be utilized to move all kinds of masses irrespective of fat, size and shape.

Automated conveyors can be run with the smallest amount of quantity of supervision all through all changes, vacations and weekends. By using these conveyors, you save promptly lost because of staff lateness and absenteeism. Moreover, the range for human error is less and the right components are quickly provided to their supposed places in a smooth manner. Automated conveyor programs are most useful fitted to large volume transport schedules. When you use automatic conveyors, you can minimize substance and product reduction because of inconsistent handling, breakage and staff inattention.

The similar character of the task plays a part in the tedium that personnel can knowledge throughout performance of unique tasks. This could cause human mistakes resulting in large losses.

buy lexapro online blackmenheal.org/wp-content/languages/new/us/lexapro.html no prescription

If you want accuracy and repeatability, automation is your absolute best guess to create high-quality effects time and time again. Worker satisfaction can be guaranteed in full because of the comfort level supplied by ergonomically developed automated conveyor techniques that minimize the necessity for personnel to perform actually challenging tasks.

Warehouses that use Conveyor Systems will not need certainly to utilize a large quantity of employees. There’s a low dependence on personnel because the conveyors can do the work of numerous employees. Firms can decrease charges and save money on individual source administration, payroll, government costs and employee instruction programs. This really is crucial in a economic circumstance that doesn’t search also promising for the future.