Certain advancements have assisted some metal architecture companies to end up being more efficient. However, many still experience a withstand somewhere; most usually within the press foot brake setup process.

Push Brake setup needs to be each efficient and precise in order to eliminate rework plus waste in the time and materials. The most expensive part of virtually any operation is within the setup while from a production standpoint, no pieces are being made. In order to achieve both reliability and speed, appropriate training and functioning procedures for recurring jobs through the standard setup process can help deliver exceptional results.

Training

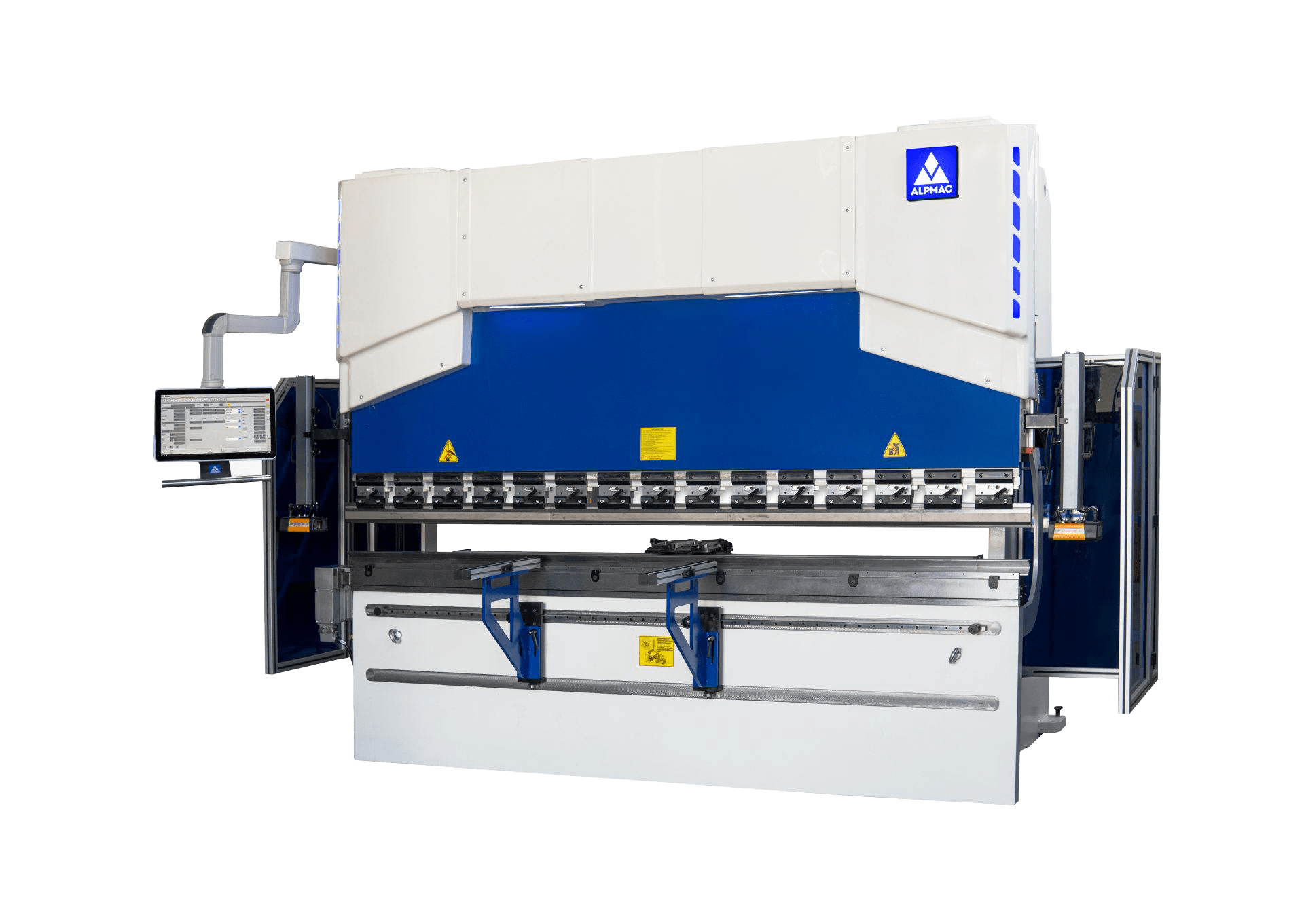

The particular press brake may be one of the particular most difficult equipment to run inside a precision metal fabrication shop. Inspite of all the technological innovation improvements, the operator needs the learn how and skills to believe through the methods to create the particular part and anticipate problems ahead involving time. This is also true right now as raw materials costs have boomed to epic proportions and excessive waste materials from bad tolerances is not the option.

Modern hit brakes have sufficient functions to take the guesswork and art out of bending with thickness compensators, automatic spring-back changes, and so forth. While these types of features are important, the feature richness just adds in order to the knowledge wanted by the operator to understand the create possibilities.

Options abound and proper training is required on how to properly influence the right alternatives the press brake offers both with regard to efficiency of operation and accuracy associated with reproducing the desired element.

Standard Operating Procedures

Metal fabrication outlets today face the particular demands of a lot of small runs and tighter tolerance requirements by way of a customers. Implementing standard operating procedures and proper teaching in process setup go an extended way towards achieving consistency in making high quality components with minimal waste. This is specially true when evaluating part variations produced by multiple workers with different skill levels.

For recurring jobs, setup sheets may help achieve consistency and efficiency as these people capture previous information of best practices, help eliminate errors of omission, and help effectiveness as one does not need to number everything out through scratch each time. The particular setup lists could include tools needed, setup sequences, configurations and other certain advice about the job.

Some sort of setup procedure may contain these seven steps:

1) Overview enter: This needs to be performed the first moment a job is run and after that the data captured with regard to review on future runs. Basics will be: Material thickness plus type, any flange dimensions and tolerances, angles required and the inside radius, plus blank dimensions. On many images the inside radius is not chosen but this is definitely very important for determining the type of tooling expected and in a few cases which click brake.

2) Select the tooling depending in the event that bottom bending, coining, air bending or any other application is necesary.

3) Determine tonnage requirements depending after the bending technique selected in typically the previous step.

4) Position tooling possibly centered or off-center as appropriate and make any adjustments. three roller plate rolling machine is typically the virtually all frustrating but treatment is needed for accuracy.

5) Set typically the program parameters regarding the press brake pedal control system. This area is another efficiency training opportunity as this step can be time consuming nevertheless little time is definitely focused on training, especially for the more advanced features currently available.

6) Perform a check bend and create any adjustments. Make use of scrap whenever probable to save upon material costs. A new properly trained operator can make alterations quickly and proficiently. Once a great part is shaped, don’t allow any further adjustments in the particular settings.

7) Start off the run nevertheless set a testing interval to help make sure the portion remains produced along with the proper tolerances.

The use involving consistent training methods can help employees become more effective when working with equipment plus the general procedure. This simple technique enables fabrication outlets to alleviate the rising cost regarding materials while even now creating a consistently higher quality product. Utilizing the specialty management features of the modern press brake, individual knowledge, and consistent production process will result in reduced scrap and even increased productivity.